Fire Stopping

The buildings are compartmentalized into different occupancies with fire rated walls and floors where Fire Separations are required to be maintained to contain the fire (and smoke) from spreading. The Building Codes have very clear requirements on passive fire protection. Fire investigative reports have consistently shown that unprotected or improperly protected penetrations and joints have caused millions of dollars in property damage and contributed to the loss of life and injuries due to the uncontrolled migration of fire, smoke and toxic gases. This is accomplished by Fire Stopping ALL penetrations through fire rated walls and floors.

Firestopping is a fire protection system made of various components used to seal openings and joints in fire resistance rated wall and/or floor assemblies.

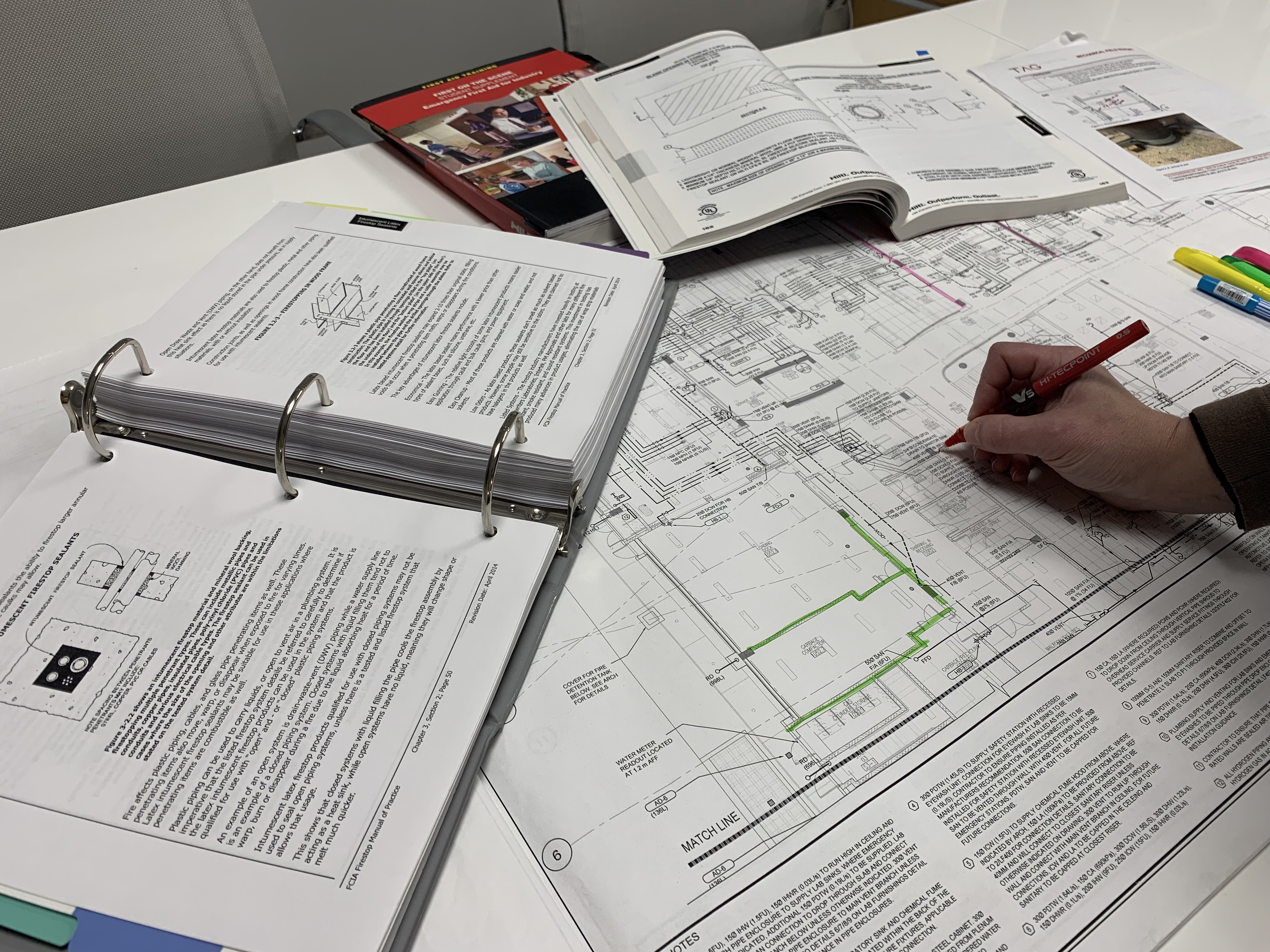

FIRE STOPPING REVIEW PROCESS

1. Shop Drawings Review

The contractor decides which manufacturer will be used, attains shop drawings for Fire Stopping Listings based on the pipe material, use and wall/floor assemblies, and submitted to the engineer for review.

The local authority having jurisdiction (AHJ) must approve Firestop system details and Firestop products. Manufacturer cut sheets form part of the shop drawings. They include detailed instructions for the installation and are often accepted if they are generated by an approved testing agency. If details, products and specifications are not sufficient to provide clear directions to the general contractor and firestop installer, the submittals will be noted as incomplete and returned to the contractor to be resubmitted with the required information. When the plans and specifications are clear and complete, most field problems with firestop systems can be avoided.

2. Pre-Construction Meeting

This meeting is the perfect opportunity to initiate discussion on the coordination of work among the trades, the general contractor and building inspector is during the pre-construction meeting. This discussion is important since the application of firestop protection systems is affected by the work of many trades including mechanical, plumbing, electrical, walls and ceilings, fire protection, etc. An early discussion of who is going to be responsible for restoration of the fire resistance ratings will eliminate aggravation and expense later in the construction. If there is no clear delegation of responsibility for the installation of firestop systems for the penetrations and joints, it is vital that the general contractor understand that it is his responsibility to ensure the fire resistance ratings of the structure.

3. Fire Stopping Installation

Depending upon how firestopping will be done on a project, the contractor(s) will proceed to install the fire stopping. It is important that the individuals doing the installation are properly qualified by getting training by the manufacturer. This training is usually provided by the manufacturer free of charge. Point to noted there is that the installation MUST follow the listing instructions exactly. Any variation from what the manufacturer has noted, will render the installation invalid and the manufacturer will not stand behind it. This means if there is ever a fire, the fire stopping manufacturer will take a position that the listing is not done in accordance with the test listing instructions and hence cannot be backed up.

4. Review by the Engineer

The ability of penetration firestop systems and fire resistive joint systems to perform their intended function of fire containment is directly related to the quality of their installations. Thorough inspection is an integral component of any passive fire protection quality control program. It is not usually feasible to visually inspect each penetration and the entire length of every joint. We at TAG Engineering, start with sample reviews. If there were 20 or 30 penetrations, we will observe 2 or 3 representative installations, in other words 10% of the penetrations will be reviewed. If an installation fails, we will have that listed as deficient and add one additional to the number.

Glossary.............................................................................................................................................

Annular Space: The opening around a penetrating item.

F Rating: The time period that the through-penetration firestop system limits the spread of fire through the penetration when tested in accordance with ASTM E 814 or UL1479.

Fireblocking: Building materials, or materials approved for use as fireblocking, installed to resist the free passage of flame to other areas of the building through concealed spaces.

Fire-Resistant Joint System or Fire Stop Listing: An assemblage of specific materials or products that are designed, tested and fire-resistance rated in accordance with either ASTM E 1966 or UL 2079 to resist for a prescribed period of time the passage of fire through joints made in or between fire-resistance rated assemblies.

Intumescent is a substance which swells as a result of heat exposure, thus increasing in volume and decreasing in density.

Joint: The opening in or between adjacent assemblies that is created due to building tolerances, or is designed to allow independent movement of the building in any plane caused by thermal, seismic, wind or any other loading.

L Rating: The air leakage rating of a through penetration firestop system or a fire-resistant joint system when tested in accordance with UL 1479 or UL 2079, respectively.

Membrane Penetration: A breach in one side of a floor-ceiling, roof-ceiling or wall assembly to accommodate an item installed into or passing through the breach.

Penetration Firestop: A through-penetration firestop or a membrane-penetration firestop.

Perimeter Fire Barrier System: An assemblage of specific materials along the perimeter of a floor with an hourly fire endurance rating and a non-rated exterior curtain wall to ensure continuity of the separating function of the floor assembly. Tested in accordance with ASTM E2307.

Splice: The result of a factory and/or field method of joining or connecting two or more lengths of a fire-resistant joint system into a continuous entity.

Penetration Firestop: A through-penetration firestop or a membrane-penetration firestop. *Although ducts may be considered penetrations, the requirements for maintaining the fire rating of the assembly penetrated by ducts are beyond the scope of this document.

T Rating: The time period that the penetration firestop system, including the penetrating item, limits the maximum temperature rise to 325°F (163°C) above its initial temperature through the penetration on the non-fire side when tested in accordance with ASTM E 814 or UL 1479.

Through-Penetration Firestop System: An assemblage consisting of a fire-resistance-rated floor, floor-ceiling, or wall assembly, one or more penetrating items passing through the breaches in both sides of the assembly and the materials or devices, or both, installed to resist the spread of fire through the assembly for a prescribed period of time.

.

MECHANICAL ENGINEERING

- Facilities Assessment

- HVAC Design

- Plumbing Design

- Central Utility Plants

- Chilled water systems

- Hot water Systems

- Commerical Kitchens

- Pumps and piping

- Building Automation

- ASHRAE 90.1

- ASHRAE 62.1

- NECB Compliance

ELECTRICAL ENGINEERING

- Lighting Design

- Lighting Analysis

- Life Safety Systems

- Load Calculations

- Power layout

- Main Utility Connection

- Electrical Room Layout

- Fire Alarm System

- Voice & Data System

- ASHRAE 90.1

- NECB Compliance

FIRE PROTECTION

- Fire Protection Systems

- Sprinkler Layout Design

- Commercial Kitchens

- Data Centers

- Clean Agent

- Dry Pre-action Systems

PROJECT MANAGEMENT

- Project Planning

- Cost and bid analysis

- Contract Management

- Budget development and approval

- Equipment Procurement

- Turnkey Solutions

- Site supervision

- Quality control

- Training for client key personnel

NEED HELP?

LET'S CONNECT